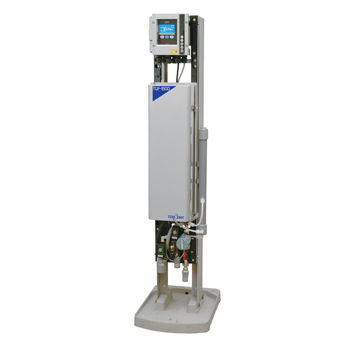

The TUF 1690 turbidity sensor and analyzer with automatic cleaning is based on the reflected scattered light measurement method. Water is guided into a measuring tank and vented. It is then directed past an optical system consisting of an LED and a light-sensitive sensor.

Particles (the turbidity) in the water reflect the light. The reflected light then reaches the reflection sensor, which is positioned at a 90-degree angle to the emitting diode. The reflected light is converted into an electrical signal. The intensity of the reflected light is proportional to the amount of particles present in the water. By placing the sensor unit underwater, disruptive influences such as surface waves or floating objects are largely avoided.

Application areas of the turbidity sensor and analyzer

Turbidity measuring devices are essential in water and wastewater treatment, food and beverage industry, chemical and pharmaceutical industry, as well as in the milk and dairy industry. They ensure the purity and quality of liquids. They also play an important role in environmental monitoring for detecting contaminants and ensuring quality control. These devices are crucial for safety and consistency of quality in these industries.